Get MZG Dovetail Milling Cutters 60 welding blade dovetail groove milling machine of tungsten steel mold tooling guide processing only US $17.32 - 81.62 just for today

click button to claim coupon

Satisfaction and the overall shopping experience ranks high on the goal list of buyers. But internet shopping, opposed to shopping a IT store can be challenging. Within a Brick and Mortar store shopping can be carried out with physical examination of products and quality judgments are easier than you think to make. Shopping online presents its challenges in that digital vision can be manipulated and a product's appearance may be polished. So , before buying handmade art work products online learn to value the handmade aspect of the MZG Dovetail Milling Cutters 60 welding blade dovetail groove milling machine of tungsten steel mold tooling guide processing you plan to buy. With multiple product categories and a vast array of products obtainable within those categories it's important to develop skill sets for the coffee lover.

MZG Dovetail Milling Cutters 60 welding blade dovetail groove milling machine of tungsten steel mold tooling guide processing

1.MZG Milling Tools Item Specifics

2.MZG Milling Tools Product Photo

3.MZG Milling Tools Packing Info

4.MZG Milling Tools Parameter

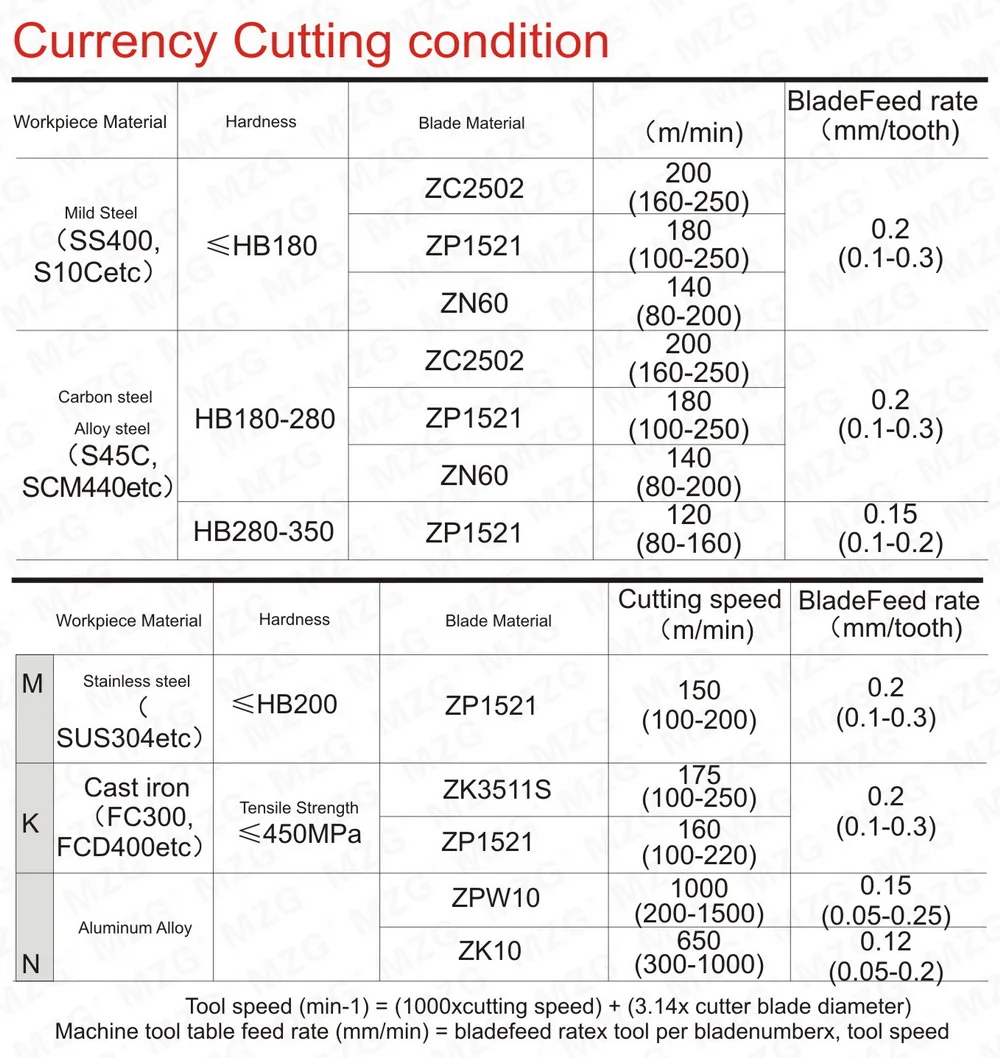

5.MZG Milling Tools Instruction

Safety Notes for Cutting Tool

1 Introduction

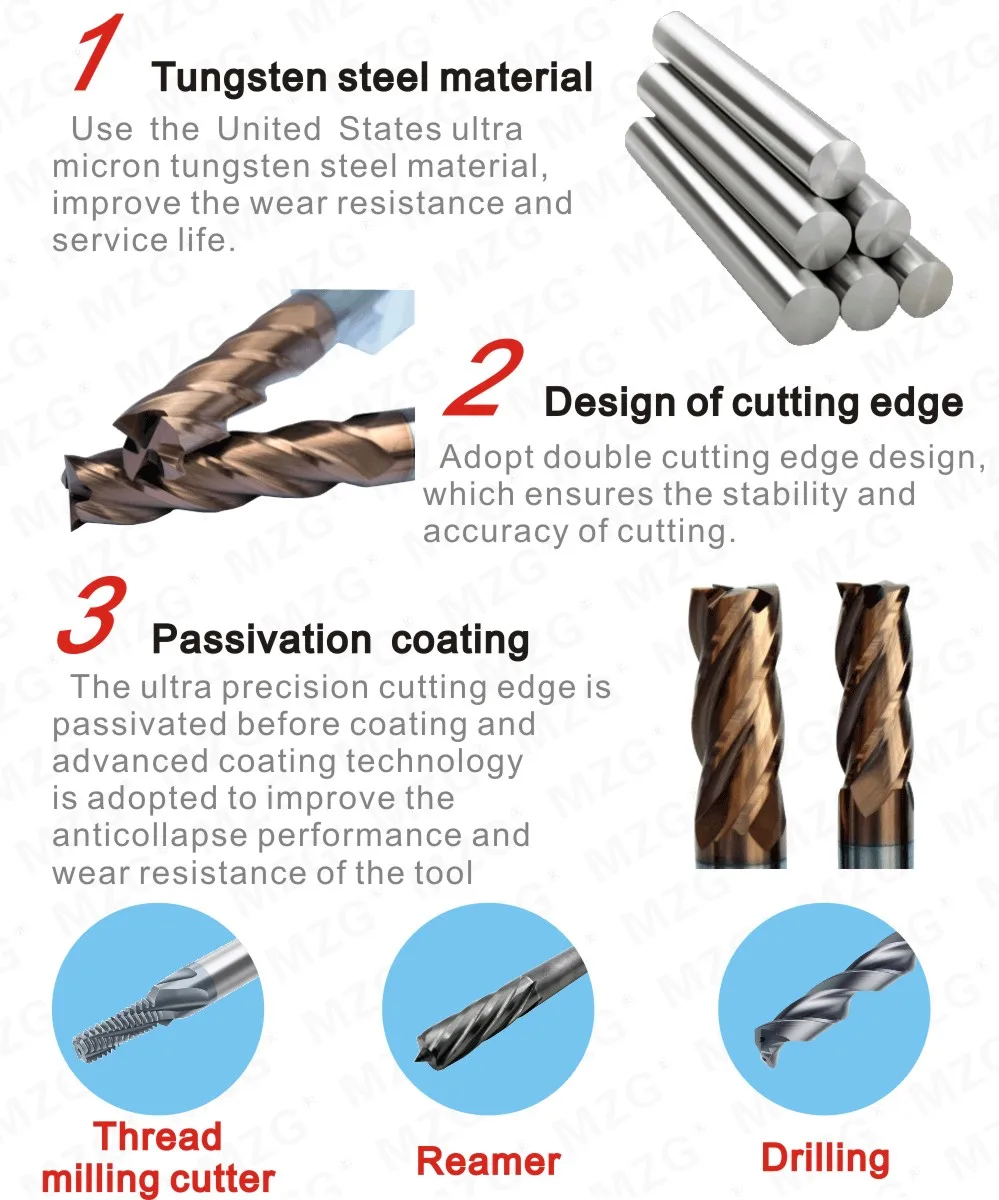

2 Basis Information for Cutting Tool Materials

2-1 Technical Terms

2-2 Physical Properties

2-3 Composition

Precaution for using cutting tool

1.General Cutting Tools

Precaution for using cutting tools

Precariousness: Direct touch to a sharp cutting edge may cause injury.

Countermeasures: When you set up tools to the machine or take tools out of the case, please wear protective gloves.

Precariousness: Misuse or inappropriate working conditions may cause tool breakage or dispersion of broken pieces.

Countermeasures:Please use safety item, such as safety glasses and protective gloves

Please use in the range of our recommended cutting condition. See our catalog or instruction manuals.

Precariousness: Excessive impact or heavy wear will increase cutting resistance and may cause tool breakage and dispersion of broken pieces.

Countermeasures: Please use safety item, such as safety glasses and protective gloves

Early exchanging tools is preferable.

Precariousness: Dispersion of heated or prolonged chips may cause injury or burn.

Countermeasures: Please use safety item, such as safety glasses and protective gloves

For chips removal, please stop the machine beforehand and use safety items, such as safety glasses and protectives gloves.

Precariousness: Tools and materials reach high temperatures during cutting operation. Direct touch to the tools and materials shortly after cutting may cause burn.

Countermeasures:Please use safety item, such as safety glasses and protective gloves

Precariousness: Sparks, generation of heat or chips in high temperature during operation may cause file.

Countermeasures: Please do not operate around Hazardous zone, in which there is some possibility of fire or explosion.

In case of using oil-coolant, please make sure there is sufficient fire-protection equipment.

Precariousness: Lack of dynamic balance during high-speed revolutions leads to vibrations which can make the tool break.

Countermeasures: Please use safety item, such as safety glasses and protective gloves

Please conduct test-operation before cutting, and confirm that there is no vibration or unusual sound.

Precariousness: Direct touch to the burs which were generated on the rough surface of the workpiece may cause injury.

Countermeasures: Do not touch the workpiece with bare hand.

2.Indexable Cutting Tools

Precariousness: If the insert or other tool parts are not installed properly, they can fall down or break which may cause injuries.

Countermeasures: Please clean up insert pockets or clamping parts before setting insert.

Please set up inserts with supplied wrench only, and confirm that the inserts or parts are clamped completely. Never use inserts or parts other than those prescribed.

Precariousness: If inserts are clamped too tightly by supplementary tools like pipe etc. inserts or body may break.

Countermeasures: Do not use aids such as pipes. Please set up using supplied wrench only.

Precariousness: When tools are used in high-speed revolution, inserts or parts may burst out of the body due to centrifugal force. When handling, please pay special handling to safety.

Countermeasures: Please use in the range of our recommended cutting condition. Accuracy and balance of machine spindle should be checked and adjusted regularly to prevent wear of the bearing due to eccentric rotation.

3.Milling Cutters and other Cutting Tools

Precariousness: Since milling cutter have sharp edged, direct contact with bare hands may cause injury

Countermeasures: Please use safety item, such as safety glasses and protective gloves

Precariousness: If a cutter lack balance, the tool can start to vibrate. The dispersion of broken piece can cause injuries.

Countermeasures: Please use in the range of our recommended cutting condition.

Accuracy and balance of machine spindle should be checked and adjusted regularly to prevent wear of the bearing due to eccentric rotation.

4.Drilling

Precariousness: When drilling a through-bore, it is possible that a disc is created during the drilling procedure that can fly out of the workpiece at a high speed.

This is very dangerous since the disc has sharp edges.

Countermeasures: Please use safety items, such as safety glasses and protective gloves. Also attach a cover on a chuck part.

5.Brazed Tools

Precariousness: Dispersion of falling down of broken inserts may cause injury.

Countermeasures:Please Check that the cutting inserts are brazed firmly before use.

Please do not use brazed tools in the condition that requires high cutting temperature.

6.Others

Precariousness: If Brazing is carried out many times, the strength of carbide insert is deteriorated and can break easily during cutting

Countermeasures: Please do not use tools that have brazed several times. The quality of the tool deteriorates.

Precariousness: The tools can only be used for the appropriate application. It may damage tools and machines.

Countermeasures: Please follow our recommended usage for the tools.

6.MZG Milling Tools Application

Application Machine:

- Milling machine

- Milling Center

- Large-scale Milling machine

Processing mode and Finished product samples

- Shoulder Milling

- Thread Milling

- Inner Hole Boring

- Fine Hole Boring

- External Boring

- Face Milling

- T Groove End Milling

7.Buying Tips

1.Picture :

- The picture showing at our store are taken by MZG on the true products. Because of different light condition or camera problem, if the color of packing is a little different,that would be normal.,

2.Payment :

- When make payment using ESCROW your money is deposited securely we accept ESCROW. Credit Cards, T/T, West Union in your account.

- Money is only released to us after you confirm delivery.

- If you have any problem of payment, please contact us asap.

3.Refund :

- 100% Money Back Guarantee on each item Please contact us within 24 hours upon your receipt of the item.A refund will be rendered in the event that the item(s) is not as described and once the item(s)has been sent back in original condition..

4.Delivery :

- EMS : 5-15 days to worldwide Fast, cost normal

- TNT : 5-15 days to worldwide Fast, cost high

- CHINA POST : 12-26 days to worldwide slow, cost low

5.Feedback :

- Your satisfaction and positive feedback is very important to us. Please leave positive feedback and 5 stars if you are satisfied with our items and service.

- If you have any problems with our items or services, please feel free to contact us first before you leave negative feedback.

- We will solve the problems quickly and promise you 100% good products and services.

- Your encouragement and support is our continuously forward momentum.

8.MZG Machine Tools Brand Introduction

Improve THE production Efficiency by 30%

Specialize In Turning, Milling, Threading and Boring machining field

No comments:

Write comments